Design of Plastic Parts – Noex's Offer

Our offer includes, among other things, design of plastic parts– from the method of manufacturing to shape, material, and functionality. This allows us to provide our clients with almost unlimited possibilities regarding the characteristics, parameters, shapes, or intended use of the plastic products they need. The preparation of plastic parts requires considering many factors, both in terms of the material itself and the features of the finished product.

When creating a design, it is essential to consider the specifics of the production process, which helps avoid errors that could reduce product quality. Design of plastic parts should also be particularly meticulous at every stage. This ensures high-quality, repeatable parts that are precisely and aesthetically finished. The quality of our designs is ensured by modern computer software.

How Does the Design of Plastic Parts Work?

Design of plastic parts is a process that requires the involvement of specialists in materials engineering. A key aspect is the preparation of a mold or die in which the specific component will be manufactured. Another important factor is selecting the right plastic material, whose properties will meet the clients' needs. Our technology allows us to use a wide range of materials in production, including recycled raw materials.

The next step is creating a model that enables precise design of the part and mold. This stage allows for the structural analysis of the element and early detection of design errors, leading to reduced production costs and shorter project completion times. Once the design phase of the parts and mold is completed, the production process begins, using methods such as plastic injection molding or 3D printing. Finally, the manufactured components undergo quality control processes.

Not Only the Design of Plastic Parts – Noex's Full Offer

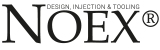

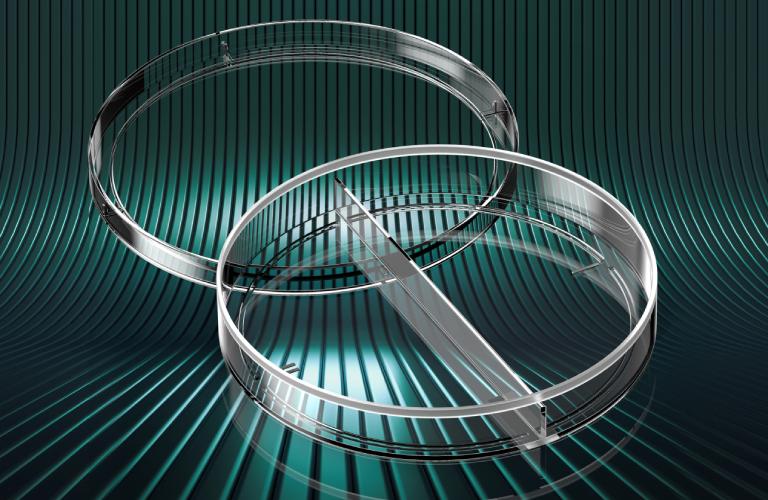

Although design of plastic parts is a significant part of our operations, it does not encompass the entire Noex offer. We manufacture components from various materials, including plastic, glass, and metals. Our specialty is the production of plastic parts using injection molding. We are engaged in manufacturing promotional items and are also a producer of laboratory accessories. Caring for the environment, we have introduced ECO plastic products into our offer.

A key element of our business is our tool shop. We have extensive experience in designing and manufacturing injection molds, dies, and plastic components. The high precision of execution and the ability to produce large quantities of elements simultaneously ensure competitive prices and reduced order fulfillment times. We can adapt to the specific requirements of each client and offer the best solutions.