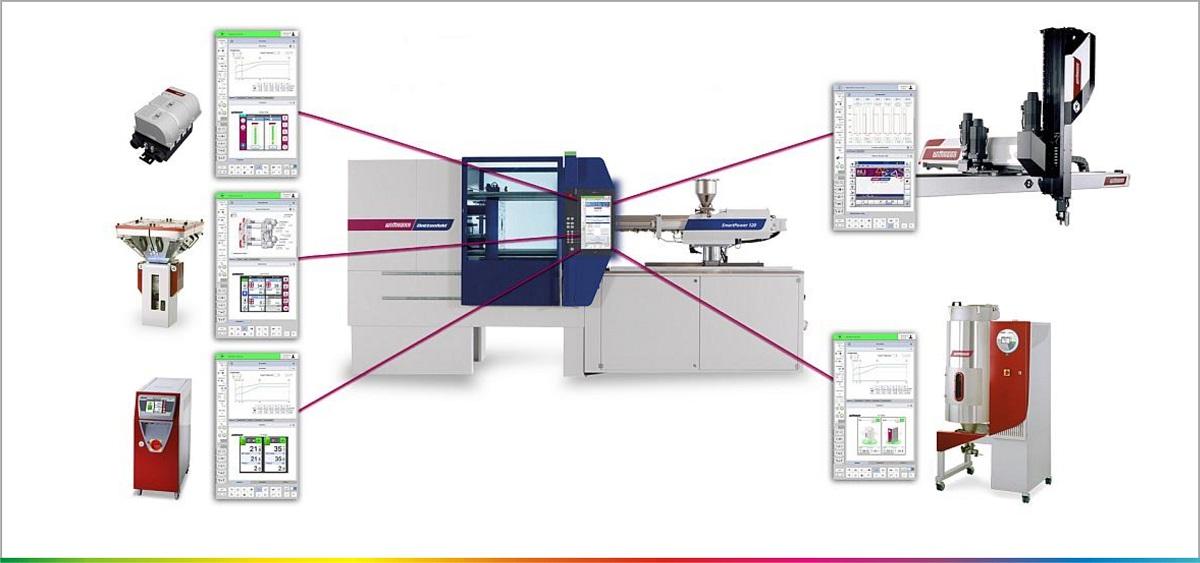

Wittmann 4.0 processing

In cooperation with Wittmann-Battenfeld, we have commenced the process of implementing the WITTMANN 4.0 system, i.e., linking each production cell (communication between machines, robots and peripheral devices) with the company's IT network. This process enables automatic identification of machines and all auxiliary equipment. In addition, the Wittmann 4.0 system allows automatic configuration of the devices employed in our injection moulding room and tool room, which expedites the entire manufacturing process and eliminates human error.

An important aspect related to the implementation of the Wittmann 4.0 system is increasing data security throughout the entire manufacturing process. Hooking-up individual elements to the company’s IT network allowed us to create a coherent and secure working environment. Wittmann 4.0 also provides unlimited access via the WiBa QuickLook mobile app. It allows employees to monitor the manufacturing process in real time and receive alerts in the event of a malfunction or failure.

The Wittmann 4.0 system enables information exchange with other CMS monitoring systems, and remote control over individual manufacturing elements. All this makes up a comprehensive and complete image of an entire manufacturing process, which allows us to rapidly respond to any problems or defects. An undoubted advantage of the Wittmann 4.0 system is the fact that it offers opening doors to a new world of production – Industry 4.0. This state-of-the-art solution makes the entire manufacturing process become more effective and quicker.