CNC services – modern CNC machines

Our company offers CNC services implementing with the use of modern numerically controlled machines. Our service range includes manufacturing steel, aluminium and copper components, as well as injection moulds and punching dies employed in our injection moulding room. Our machinery park contains the equipment by renowned manufacturers, such as Charmilles, DMG or HASS. They allow us to handle even the most complex orders. All components leaving our workshop are characterized by high quality, precise finishing and durability. This is owing to not only our state-of-the-art CNC machines, but also our highly qualified staff with vast experience in CNC machining of different materials.

Applications of CNC services

CNC, which stands for Computer Numerical Control, is method of programming machine tools, which enable precise execution of advanced plastic or metal components. It is widely applied in such industries as the automotive, medical or military. CNC services provide the possibility of not only increasing manufacturing efficiency, but also achieve significantly higher product quality. All this owing to precise and accurate operations of computer-controlled machine tools. A CNC machine allows to easily manufacture models and products prior to marketing them. CNC machines enable fast component prototyping, which, in turn, leads to shortening the time-to-market and reducing manufacturing costs of a product.

Advantages of CNC machining

CNC services are employed in different industries to execute elements made of such materials as steel, copper or plastics. The top advantages of CNC machining include high precision that allows to achieve effects impossible in the case of manual machining. When it comes to mass production, the meticulousness of CNC machining enables attaining high dimensional repeatability and, in most cases, eliminating the need for manual measurement of each of the manufactured parts. It is a state-of-the-art method that allows to cut costs and increase manufacturing efficiency. Owing to the fact that the process is automatic, based on an appropriately programmed computer, designs are identical. This translates to significantly larger material saving and time-efficiency.

Another advantage of CNC machining is the ability to manufacture non-standard shapes. With this process, we are able to rapidly and easily manufacture a variety of workpieces and injection moulds for plastics. CNC services ensure creative freedom in terms of irregular and complex shapes, which provides the designers with considerably greater product creation possibilities. CNC machining enables also employing various materials for the manufacturing process. This allows to match the best raw materials that meets customer requirements in terms of durability and quality, and the manufacturing of which will be economically viable. The last, but not least, important advantage of CNC machining is the option to automate the process. This technology enables remote programming of a manufacturing machine based on the current demand.

Types of CNC services

One of the most often chosen CNC services is numerically controlled turning. It involves machining elements using a lather that moves relative to the machined item. Turning allows to achieve elements of various shapes and dimensions, depending on client needs. It can be employed to manufacture precise pins, axles, shafts and other parts. Another popular CNC service offered by our company is milling. This method involves a machine tool equipped with cutters for material forming and cutting, and its primary task is to remove excess material from the product surface. Milling enables achieving materials of highly complex shapes, as well as precise and accurate surface finishing.

Laser welding is yet another compelling CNC service. It involves fusing materials via a laser beam. It is a solution that is perfect for tasks that require obtaining very fast and precise results. Laser welding enables fusing both thick and thin metal layers. Metal printing is also one of our CNC services. It involves creating elements of extremely complex shapes that would be hard to obtain otherwise. Another type of CNC services we provide is EDM (electrical discharge machining). It is a process wherein the material is removed via electrical discharge. The technique enables precise removal of material from robust and hard-to-reach parts.

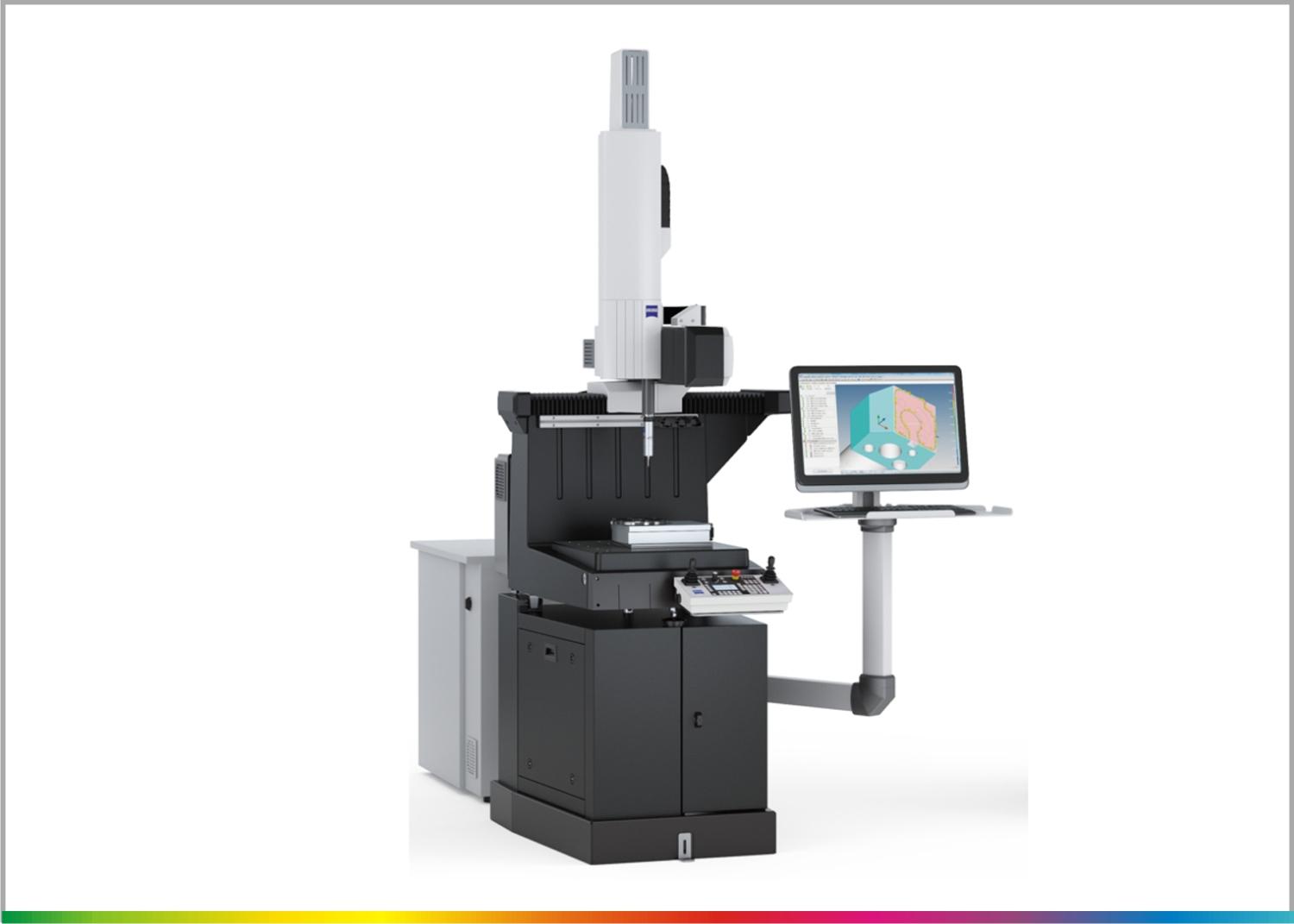

Our machinery park consists of more than 30 specialized machines and auxiliary equipment pieces:

- CNC milling machines (CHARMILLES, DMG, HASS),

- EDMs – electrical discharge machines (CHARMILLES),

- wire cutting machines (CHARMILLES),

- CNC lathes,

- grinders,

- graphite machining equipment,

- laser welder,

- metal printing machines,

- measurement systems.

We encourage you to establish cooperation with us and make use of the CNC services we offer. Should you have any questions, we will happily answer them.